Oxygen-tight according to DIN 4726 (sauerstoffdicht nach DIN 4726)

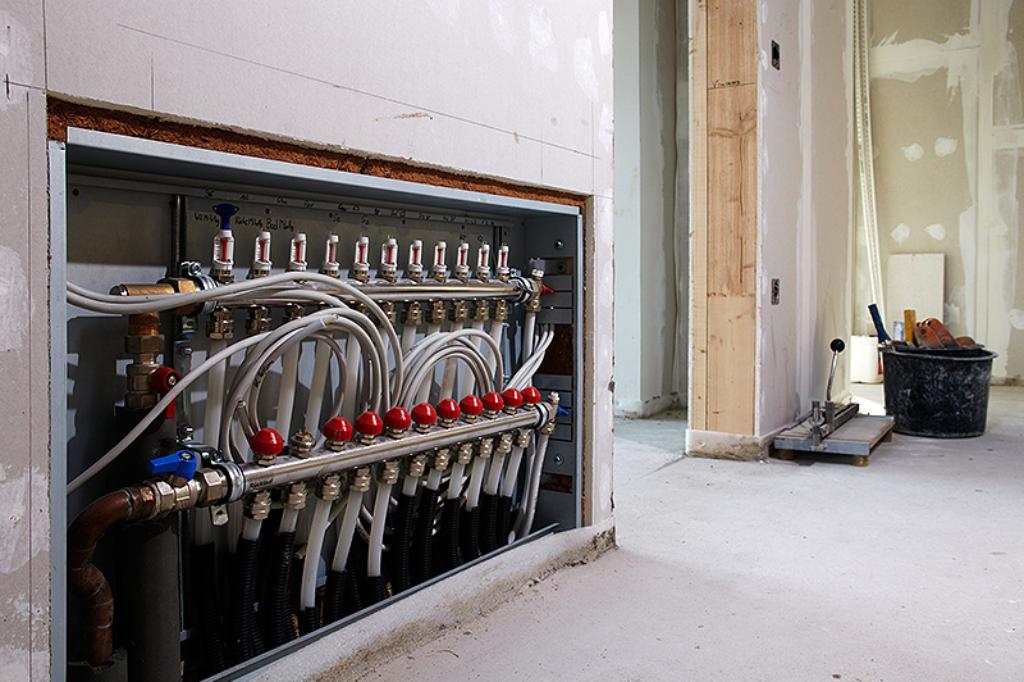

Copper or steel pipes have been used predominantly in the past in heating technology. The sector has since learnt to appreciate the benefits of plastic piping systems. Light weight and high flexibility ensure simple and fast laying.

This is why plastic pipes are used mainly when laying underfloor heating in Germany. There are also a variety of systems available for the application as radiator connecting pipes. The following materials are used:

- Polypropylene (PP)

- Crosslinked polyethylene (PE-X)

- Polybutylene (PB)

- Polyethylene with higher temperature resistance (PE-RT)

- Chlorinated polyvinyl chloride (PVC-C)

- Medium density crosslinked polyethylene (PE-MDX)

- Multilayer piping systems

As oxygen entering the heating system can result in problems with corrosion to the iron parts (heating boiler, radiators) and therefore has a significant impact upon the life of the system, all the plastic pipe systems have to be oxygen-tight according to DIN 4726.

Cofidence is good - DIN-Geprüft is better!

With the accredited and independent certification mark "DIN-Geprüft", DIN CERTCO enables the manufacturer and retailer to convince their customers of the quality of their products and provide the customer with assistance in his purchase decision; as our mark stands world-wide for confidence.

Basis of Testing

The DIN CERTCO certification scheme "Plastic piping and multilayer piping systems for warm water floor heating and radiator connecting systems" is the basis on which the mark is awarded. The scheme is based on the following standards:

- DIN 4726 "Warm water surface heating systems and radiator connecting systems - Plastics piping systems and multilayer piping systems"

- DIN EN 15015 "Plastics piping systems - Systems for hot and cold water not intended for human consumption - Performance characteristics for pipes, fittings and their joints"

- ISO 10508 "Plastics piping systems for hot and cold water installations - Guidance for classification and design"

- DIN EN ISO 9001 "Quality management systems - Requirements"

As well as on the following mentioned standards specific for material:

Polypropylene pipes (PP)

- DIN EN ISO 15874 "Plastics piping systems for hot and cold water installations - Polypropylene (PP)" - Parts1, 2, 3 and 5

Crosslinked polyethylene pipes (PE-X)

- DIN EN ISO 15875 "Plastics piping systems for hot and cold water installations - Crosslinked polyethylene (PE-X)"

Polybutene pipes (PB)

- DIN EN ISO 15876 Plastics piping systems for hot and cold water installations - Polybutylene (PB)" - Parts 1, 2, 3 and 5

Polyethylene of raised temperature resistance pipes (PE-RT)

- DIN EN ISO 22391 "Plastics piping systems for hot and cold water installations - Polyethylene of raised temperature resistance (PE-RT)" - Parts 1, 2, 3 and 5

Chlorinated polyvinyl chloride pipes (PVC-C)

- DIN EN ISO 15877 "Plastics piping systems for hot and cold water installations - Chlorinated poly(vinyl chloride) (PVC-C)"

Crosslinked medium density polyethylene pipes (PE-MDX)

- DIN 4724 "Plastic piping systems for warm water floor heating systems and radiator pipe connecting - Crosslinked polyethylene of medium density (PE-MDX)"

- DIN 16894 "Pipes of crosslinked medium density polyethylene (PE-MDX) - General quality requirements and testing"

- DIN 16895 "Crosslinked medium density polyethylene (PE-MDX) pipes - Dimensions"

Multi-layer composite pipes

- DIN EN ISO 21003 "Multilayer piping systems for hot and cold water installations inside buildings"

- DVGW W 542 "Mulitlayer piping systems inside drinking water installations - requirements and testing"

Testing and Certification

The "DIN-Geprüft" mark is only granted to those piping systems and oxygen barrier materials that are able to prove that they comply with the standards by completing a successful test in a testing laboratory recognised by DIN CERTCO and a subsequent independent assessment.

After a positive assessment, DIN CERTCO issues a certificate that is valid for 5 years. The registration number that clearly identifies the certificate is made up as follows: 3V000.

A half-yearly verification test of the product (pipe and fitting) as well as the factory production control (FPC) of the manufacturer follows. The pipes of certified distributors are only subjected to a reduced testing scope.

FAQ - Frequently Asked Questions

| Application Form for the Certification of Products | 97 KB | Download | |

| Certifiation Scheme "Plastic piping and multilayer piping systems for warm water floor heating and radiator connecting systems" | 1 MB | Download | |

| Schedule of Fees Heating Piping Systems | 144 KB | Download | |

| Decision Guide (only available in German) | 597 KB | Download | |

| Brochure Certification of Heating an Airconditioning Products | 480 KB | Download | |

| General Terms and Conditions | 327 KB | Download |

Certificate holder and testing laboratories

These topics may also be of interest to you.

Contact

We are pleased to answer your questions

DIN CERTCO Gesellschaft für Konformitätsbewertung mbH