Product Carbon Footprint (PCF) verification service

Emissions of anthropogenic greenhouse gases (GHG), which influence climate change and its effects around the world, are constantly increasing.

According to climate scientists, global carbon dioxide emissions must be reduced by up to 85 percent below 2000 levels by 2050 in order to limit the rise in global average temperature to 2 degrees Celsius above pre-industrial levels. A temperature rise above this level will have increasingly unpredictable and dangerous impacts on people and ecosystems. As a result, there is a need to step up efforts to reduce greenhouse gas emissions. The focus here should be on the deeper supply chain, the use phase, but also on recycling, as this is where the potential for reducing greenhouse gas emissions usually lies.

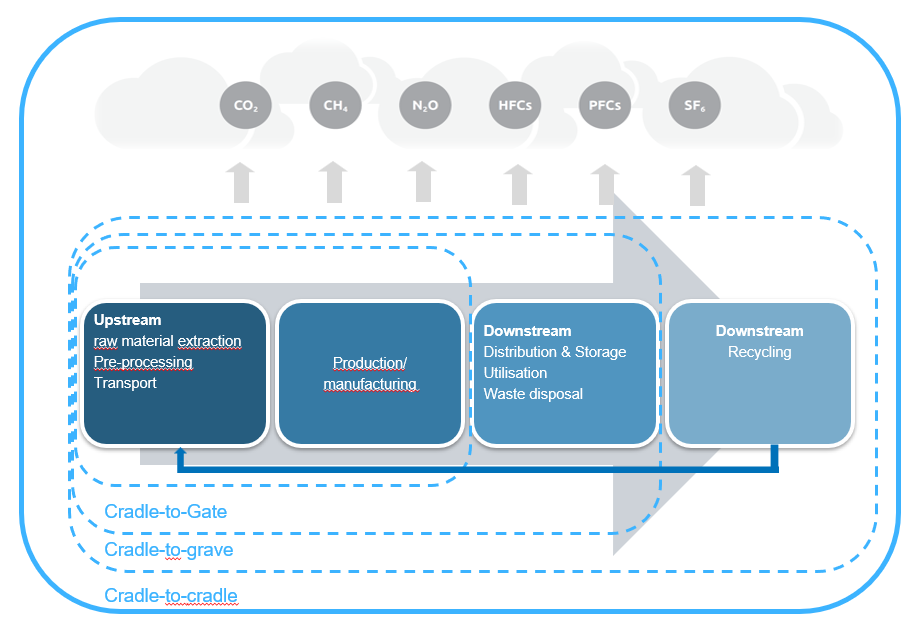

A good way to identify the reduction potential and make it transparent is to determine the product carbon footprint in accordance with DIN EN ISO 14067 or the GHG Protocol Product Life Cycle Accounting and Reporting Standard. These standards provide companies with requirements and guidelines for determining the inventory of GHG emissions and reductions from a specific product. Either individual phases or the entire life cycle of a product can be considered - from raw material extraction, logistics and production (cradle-to-gate), through to use and disposal (cradle-to-grave). In some cases, even recycling is included (cradle-to-cradle).

Trust is good - DIN-tested is better!

DIN CERTCO offers independent verification of the Product Carbon Footprint for almost all products. Thanks to our experience and expertise in the field of PCF, DIN CERTCO can verify a GHG balance and thus increase the credibility of the product brand.

With the recognized and neutral test mark "DIN-Geprüft Product carbon Footprint", DIN CERTCO offers manufacturers and distributors the opportunity to convince their customers of the quality of the data.

With the verification, manufacturers document that the products meet all the requirements specified in the DIN EN ISO 14067 standard or GHG Protocol Product Life Cycle Accounting and Reporting Standard and that the products have been voluntarily verified by neutral, independent and competent bodies.

The independent verification offers the following advantages:

- Security and transparency: Verified PCFs strengthen stakeholder confidence

- Compliance with requirements: Compliance with legal or voluntary requirements

- Improvement of environmental performance: Verified PCFs help companies to assess and improve their environmental performance

- Competitive advantage: PCFs serve as a marketing tool and offer a competitive advantage

- Risk management: Verified PCFs help companies to identify and manage environmental risks

The verification of Product Carbon Footprints is based on international standards and guidelines. These standards ensure consistency, reliability and comparability of PCFs worldwide.

Verification principles

- DIN EN ISO 14064-3:2020-05 Greenhouse gases - Part 3 : Specification with guidance for the validation and verification of greenhouse gas declarations for the verification of greenhouse gas reports

- DIN EN ISO 14065:2022-02 General principles and requirements for validation and verification bodies of environmental information

- DIN EN ISO/IEC 17029:2020-02 Conformity assessment - General principles and requirements for validation and verification bodies

Verification

Our Product Carbon Footprint (PCF) verification service provides a reliable and transparent way to measure and report the environmental impact of your products.

Our verification process includes a thorough review of data sources, calculation methods and assumptions to ensure they meet the highest standards.

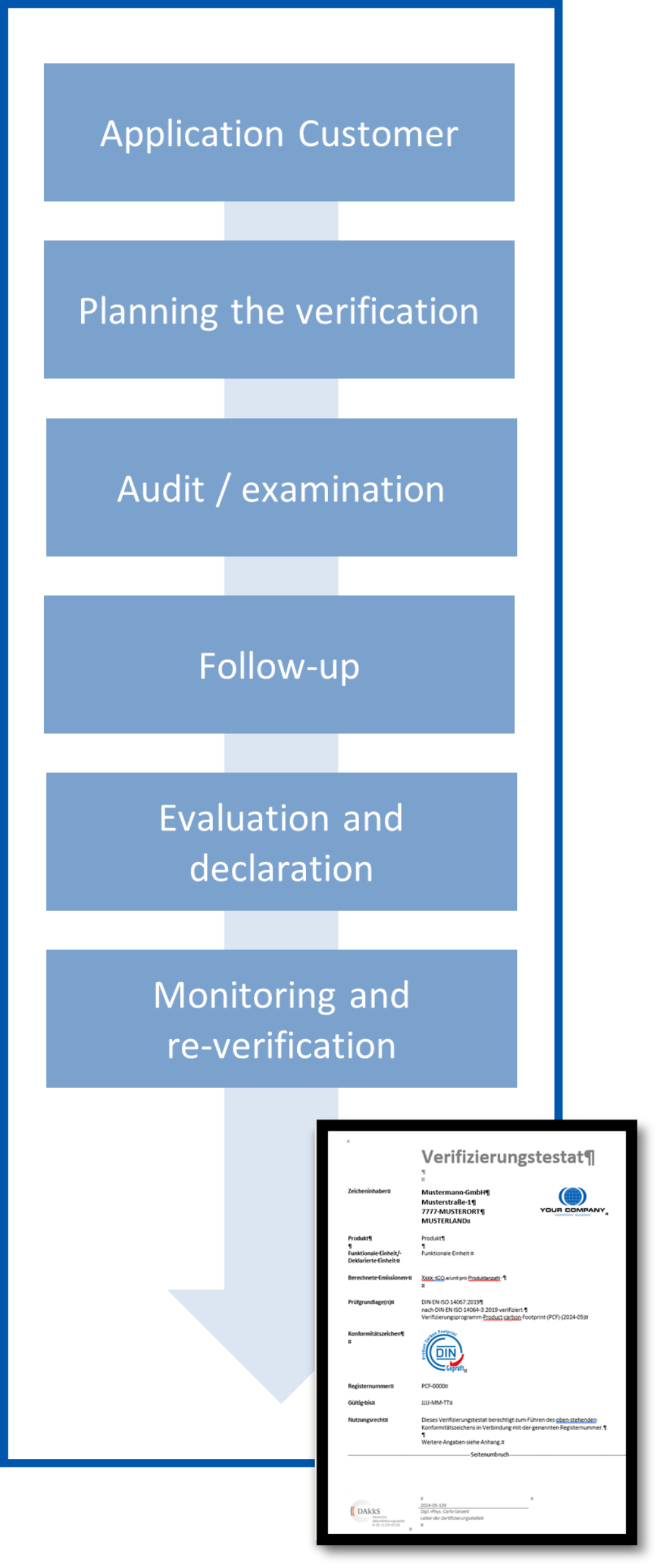

Verification process

Application

The customer sends an application with the necessary verification documents to DIN CERTCO.

DIN CERTCO clarifies the exact nature of the order, the areas of application, system boundaries, the objectives, data quality and estimates the verification effort. An offer is prepared on this basis.

Planning the verification (pre-engagement)

Verification is planned during pre-engagement. This includes the strategic analysis, risk analysis and the creation of an audit and sampling plan to collect evidence.

Audit / examination

Conducting an on-site visit to verify data collection and processing by inspecting documents and evidence.

Follow-up

Implementation of corrections, submission of missing evidence and preparation of the verification report.

Evaluation and GHG declaration

After the verification, the results are evaluated. If all requirements are met, DIN CERTCO issues a verification report and statement for the corresponding products. The verification statement is valid for the respective GHG declaration of the product and is valid for 3 years.

Monitoring and re-verification

The review of an updated report or declaration, e.g. in the event of changes to operating procedures, manufacturing methods or the material composition of components, takes place annually.

Contact

We are pleased to answer your questions

DIN CERTCO Gesellschaft für Konformitätsbewertung mbH